ceat-speciality:blogs-tags/all,ceat-speciality:blogs-tags/construction-&-industrial

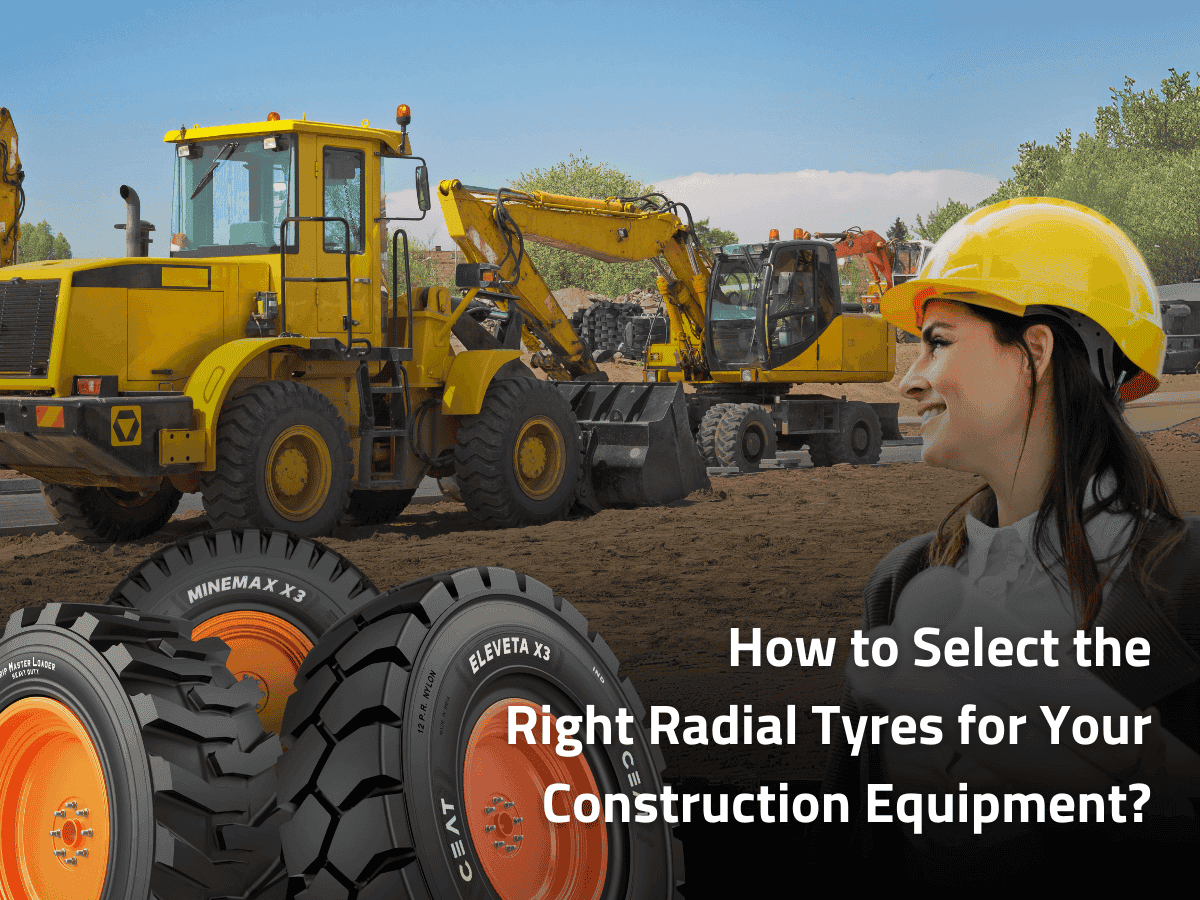

A Guide to Selecting the Right Radial Tyres for Your Construction Equipment

Wed, 12 Feb 2025 | PRODUCTS

Construction machinery, whether it is an excavator, loader, or crane, operates under tough conditions. And the construction tyres you choose will determine how effectively your equipment handles heavy loads, uneven terrains, and long working hours.

When it comes to durability and performance, radial tyres are often the preferred choice for construction equipment. However, selecting the right radial tyres for your machinery requires careful consideration of several factors.

In this guide, we will walk you through the critical aspects of choosing the right radial tyres for your construction equipment to ensure optimum performance, safety, and long-term value.

What are Radial Tyres?

Before we dive into the selection process, let us understand what radial tyres are and why they are often the preferred choice for construction equipment. Radial tyres have steel belts arranged in a radial pattern, meaning the cords run perpendicular to the direction of travel. This design provides several advantages over bias-ply tyres, including enhanced durability, improved fuel efficiency, and better handling on uneven terrains.

Radial tyres offer a greater footprint on the ground, resulting in reduced soil compaction—important when operating on soft ground—and provide better heat dissipation, which contributes to a longer service life. These features make radial tyres highly suitable for construction equipment, which is often subjected to heavy loads and long operating hours on rough, challenging surfaces.

Factors to Consider When Selecting Radial Tyres for Construction Equipment

1. Type of Equipment

The type of construction equipment you are using plays a critical role in determining the appropriate radial tyres. Construction machinery ranges from wheeled loaders and bulldozers to cranes and dump trucks, each with unique performance requirements.

For instance, a wheel loader will require tyres that provide a combination of traction, stability, and durability, as it frequently operates on rough, unpaved surfaces. On the other hand, dump trucks typically require tyres designed to handle heavy loads and deliver excellent traction in challenging conditions.

Consider the specific application of your construction equipment and match the tyre’s features to the equipment’s needs. Some tyres are designed for traction, while others focus on flotation or load-bearing capacity.

2. Load Capacity and Weight Distribution

One of the most important factors when choosing radial tyres for construction equipment is the load capacity. The tyres must be capable of handling the weight of your equipment, as well as any additional loads, such as construction materials, that the machine will carry.

Ensure that the tyres you select can support the maximum load capacity as specified by the equipment manufacturer. Pay attention to the load index and ply rating, as these indicate the strength and durability of the tyres under heavy loads.

Additionally, consider the weight distribution of your machinery. For equipment with a more uneven weight distribution (like backhoe loaders), it is essential to choose tyres that offer stability and balance to prevent excessive wear on one side.

3. Terrain Type

Construction sites are rarely uniform. From smooth asphalt to uneven, muddy, or rocky terrain, your equipment needs tyres that can perform across a range of surfaces. Different radial tyres are designed for different terrains, and selecting the right one for your construction site will optimize both performance and safety.

If you primarily work on hard, paved surfaces, look for tyres that offer durability and resistance to abrasion. For construction equipment used in rough, off-road conditions, choose tyres with a deep tread pattern that can provide maximum traction. Similarly, if you are working on soft ground or unstable soil, tyres with a wider footprint will offer better flotation to prevent the machinery from sinking or becoming bogged down.

4. Tyre Tread Pattern

The tread pattern of a radial tyre is a key factor in its performance. The tread affects the tyre’s grip, traction, and ability to disperse water and mud. There are several tread patterns to choose from, each suited for specific applications:

- All-terrain Tread: Suitable for a wide range of surfaces, these tyres provide good traction on both paved and unpaved surfaces, making them ideal for construction sites that have mixed terrain.

- Deep Tread Pattern: Best suited for off-road conditions, deep tread tyres offer excellent traction in muddy, soft, or wet conditions, which are common on construction sites.

- Smooth Tread: Ideal for paved surfaces, these tyres have minimal tread, offering better fuel efficiency and smoother rides. However, they are not suitable for rough terrains.

Consider the conditions your construction equipment will operate in to choose the best tread pattern for your tyres.

5. Durability and Wear Resistance

Construction equipment operates in some of the harshest conditions, and the tyres are constantly exposed to abrasive surfaces, heavy loads, and extreme stress. As such, durability and wear resistance are crucial when selecting radial tyres.

Choose tyres made from high-quality rubber compounds designed to withstand abrasion, punctures, and impacts. Some tyres are also designed with special features like sidewall protection to reduce the risk of damage from sharp objects or rough terrain. Look for tyres with reinforced sidewalls or additional layers for extra protection against cuts, chips, and impacts.

6. Cost and Long-Term Value

While it may be tempting to opt for the cheapest tyres, investing in high-quality radial tyres will provide better value in the long run. Premium tyres tend to last longer, offer better performance, and require fewer replacements, which can save you money over time.

Consider the total cost of ownership, including the cost of replacing tyres and the impact of tyre wear on fuel efficiency and overall performance. A well-chosen set of radial tyres can improve your construction equipment’s efficiency and reduce downtime, which can be more cost-effective than frequently replacing cheaper tyres.

Conclusion

Selecting the right radial tyres for your construction equipment is a crucial decision that impacts your machinery’s performance, safety, and operational costs. By considering the type of equipment, load capacity, terrain, tread pattern, and durability, you can ensure that your equipment performs optimally in the most demanding environments.

At CEAT Specialty, we offer a wide range of high-performance radial tyres designed specifically for construction equipment. Our tyres provide the durability, traction, and efficiency your equipment needs to thrive on the job site.