ceat-speciality:blogs-tags/all,ceat-speciality:blogs-tags/equipment

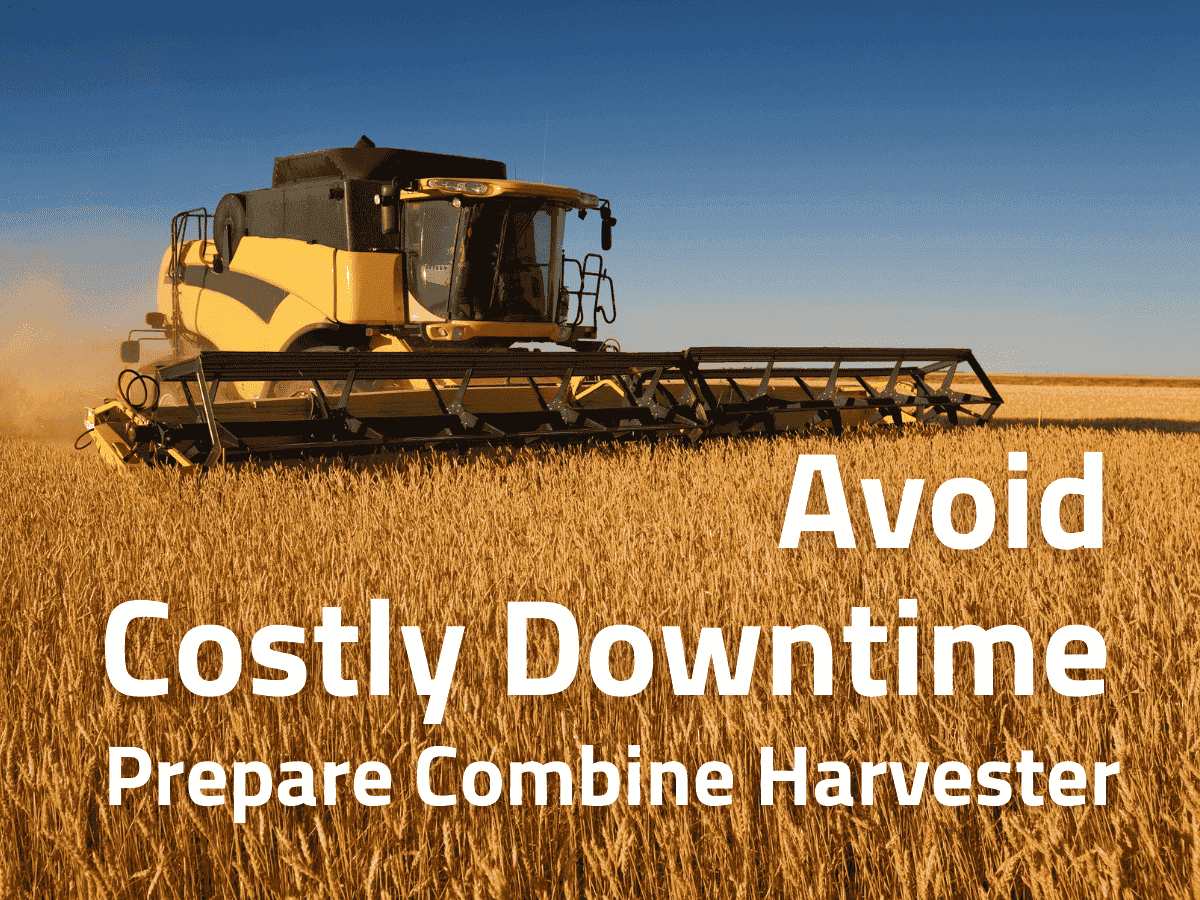

Avoid Costly Downtime: Prepare Your Combine Harvester Now

Fri, 21 Feb 2025 | PRODUCTS

Harvest season is a critical time for farmers. And the efficiency of your combine harvester can make or break your productivity. Downtime during this period can lead to significant financial losses, as crops left unharvested can deteriorate quickly. To ensure your combine harvester is ready to tackle the demands of the season, follow these essential maintenance tips and best practices.

1. Pre-Season Inspection

Before the harvest season begins, conduct a thorough inspection of your combine harvester. This step is crucial for identifying and addressing potential issues early, preventing costly breakdowns during peak operation.

- Check Fluid Levels: Ensure that all fluids, including engine oil, hydraulic fluid, and coolant, are at the correct levels. Low fluid levels can lead to overheating and mechanical failures.

- Inspect Belts and Chains: Look for signs of wear or damage on belts and chains. Replace any that show cracks or excessive wear to prevent sudden breakages.

- Examine Bearings and Gears: Check for any unusual wear on bearings and gears. Lubricate them as needed to ensure smooth operation.

2. Regular Maintenance During Harvest

Regular maintenance during the harvest season is just as important as pre-season preparation. It helps keep your combine harvester in optimal condition and minimizes the risk of unexpected breakdowns.

- Daily Cleaning: Remove debris and crop residue from the machine daily. Accumulated debris can cause overheating and reduce efficiency.

- Monitor Filters: Check and clean or replace air and fuel filters regularly. Clogged filters can restrict airflow and fuel supply, leading to reduced performance.

- Inspect Cutting Components: Regularly inspect the cutting components for wear and sharpness. Dull blades and worn parts can reduce cutting efficiency and increase fuel consumption.

3. Proper Storage and Winterisation

After the harvest season, proper storage and winterization of your combine harvester can extend its lifespan and ensure it’s ready for the next season.

- Clean Thoroughly: Before storing, clean the machine thoroughly to remove any remaining crop residue, dirt, and debris.

- Lubricate: Apply lubricants to all moving parts to prevent rust and corrosion during storage.

- Cover: Use a breathable cover to protect the machine from moisture and dust. Ensure the cover allows for air circulation to prevent mould and mildew.

4. Training and Safety

Ensuring that operators are well-trained and follow safety protocols can prevent accidents and reduce downtime.

- Operator Training: Ensure all operators are familiar with the machine’s controls and safety features. Proper training can prevent misuse and damage.

- Safety Checks: Conduct regular safety checks, including inspecting emergency stop mechanisms and safety guards. Ensure all safety features are in good working order.

5. Sustainable Practices

Incorporating sustainable practices into your farming operations can benefit the environment and improve the efficiency and longevity of your machinery.

- Soil Health: Implement practices like crop rotation and cover cropping to maintain soil health. Healthy soil reduces the strain on machinery and improves overall crop yield.

- Efficient Irrigation: Use water-efficient irrigation systems to reduce the need for frequent watering, which can strain machinery and increase fuel consumption.

CEAT Specialty: The Right Tyres for Your Combine Harvester

When it comes to the tyres on your combine harvester, choosing the right ones can significantly impact performance and efficiency. CEAT Specialty’s premium tyres are designed to meet the demands of modern farming equipment. The CEAT YIELDMAX tyres, for example, are engineered to support heavy machinery and provide higher load capacity. These tyres feature a lower lug angle around the shoulders for higher traction and sharper shoulders for excellent grip. The higher lug angle around the centre lug is for better side stability.

CEAT Specialty tyres are known for their durability and resistance to punctures, reducing the frequency of tyre maintenance and replacements. The advanced rubber compounds and tread designs ensure superior grip in various conditions, whether in muddy fields or on paved roads. By choosing CEAT Specialty tyres, you can enhance the efficiency and reliability of your combine harvester, ensuring it performs at its best during the critical harvest season.

Conclusion

Preparing your combine harvester for the harvest season is essential for avoiding costly downtime and ensuring a successful harvest. Invest time in maintenance and preparation to ensure your combine harvester is ready to deliver optimal performance when you need it most. Choose CEAT Specialty tyres to further enhance the efficiency and reliability of your combine harvester.