Search Further

Kindly select atleast one option

ceat-speciality:blogs-tags/all,ceat-speciality:blogs-tags/tyre-advice

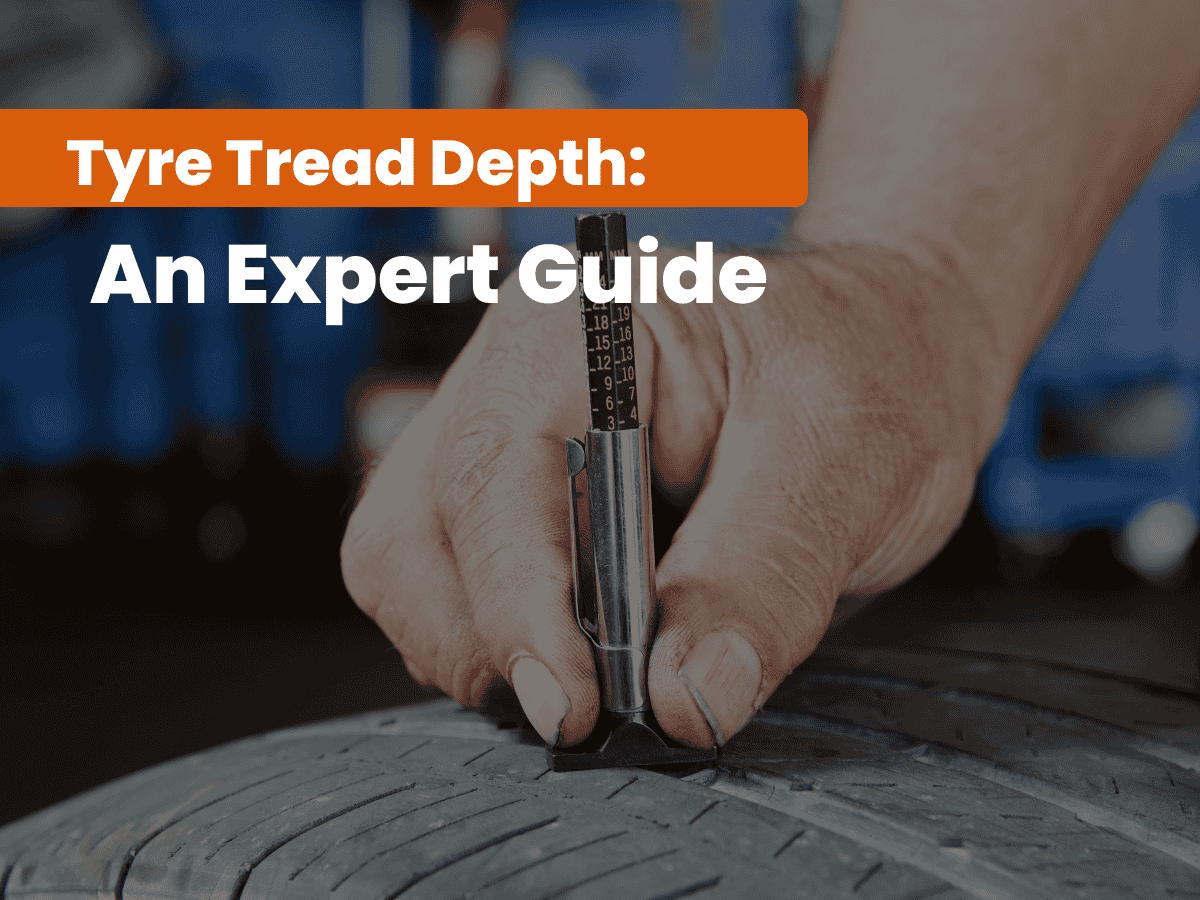

Understanding Tyre Tread Depth: A Comprehensive Expert GuideUnderstanding Tyre Tread Depth: A Comprehensive Expert Guide

When it comes to equipment safety, the condition of your tyres is one of the most important factors to consider. Among the many aspects of tyre maintenance, tread depth stands out as a critical measurement that can significantly impact your experience.

Understanding tyre tread depth is essential for ensuring proper traction, handling, and safety on the field. This comprehensive guide will take you through everything you need to know about tyre tread depth, from its role in equipment performance to how to measure it and when to replace your tyres.

What is Tyre Tread Depth?

Tyre tread depth refers to the measurement of the grooves and patterns found on the surface of your tyre. The tread plays a crucial role in maintaining traction between the tyre and the field, especially in adverse weather conditions. The deeper the tread, the more grip the tyre has, allowing for better performance in wet, icy, or muddy conditions. As the tread wears down over time, the tyre’s ability to grip the field decreases, increasing the risk of hydroplaning, poor handling, and longer stopping distances.

Tread depth is usually measured in millimetres (mm), and most tyres come with a minimum legal tread depth requirement set by vehicle safety authorities.

Why is Tread Depth Important?

Tread depth affects a tyre's ability to perform in various driving conditions, and it is directly linked to safety and equipment handling. Here’s why it’s so important:

- Traction and Grip: The primary purpose of the tread is to channel water away from the contact area between the tyre and the road surface. As the tread depth decreases, the tyre becomes less effective at displacing water, which can lead to hydroplaning – a dangerous situation where the tyre loses contact with the road.

- Braking Performance: Tyres with sufficient tread depth are better equipped to provide effective braking, especially on wet or slippery surfaces. Shallower tread depths can result in longer stopping distances, increasing the risk of accidents.

- Fuel Efficiency: Deeper tread can increase rolling resistance, which may slightly reduce fuel efficiency. However, the safety advantages far outweigh this minor fuel consumption increase, and the difference is often negligible compared to the overall safety benefit of having adequate tread.

- Longevity and Durability: The condition of the tread also indicates the overall health of the tyre. A well-maintained farm tyre with proper tread depth will generally last longer and perform better than one with worn-down tread.

Legal Tread Depth Requirements

In the UK, the legal minimum tread depth for tyres is 1.6mm across the central three-quarters of the tyre width and around the entire circumference. This is the absolute minimum allowed for safety. However, experts recommend replacing tyres when the tread depth falls below 3mm for optimal safety, especially in wet conditions, as the performance of tyres with shallow tread is significantly compromised in such weather.

While 1.6mm may meet the legal requirements, it is not a recommended level for safe driving. Many professional drivers, car manufacturers, and tyre experts suggest that tyres should be replaced when tread depth reaches 3mm, as this ensures better safety, particularly during heavy rain.

How to Measure Tyre Tread Depth?

Measuring the tread depth of your tyres is relatively simple, and you can do it yourself using a few different methods:

- Tread Depth Gauge: The most accurate way to measure tread depth is by using a tread depth gauge, which is an affordable tool available at most automotive stores. Simply insert the gauge into the tread grooves, and it will give you a reading in millimetres.

- Penny Test: If you don't have a tread depth gauge, you can use a penny to check the depth. Insert the penny into the tread groove with the Queen’s head facing down. If you can see the top of her head, the tread is worn down to below 1.6mm, and the tyre should be replaced.

- Wear Indicators: Most tyres come with built-in wear indicators – small raised bars that are located in the grooves of the tyre. These bars become visible when the tread wears down to a critical level, usually around 1.6mm.

- Visual Inspection: Regularly inspect the tyres for signs of uneven wear. If the tread is uneven, it could indicate alignment issues, underinflation, or other problems that may require attention.

When to Replace Your Tyres?

Even if your tyres are not yet at the legal limit, there are several signs that indicate it's time to replace them:

- Worn Tread: If your tread is approaching or below the 3mm mark, it’s time to start thinking about a replacement. Driving on tyres with shallow tread can severely impact your safety, especially when driving in the rain.

- Cracks, Bulges, or Cuts: Visible damage to the tyre sidewalls, such as cracks or bulges, is a clear indication that the tyre is unsafe to use. Such damage can cause a blowout or loss of air pressure.

- Vibration or Noise: Excessive vibration or unusual noise while driving may indicate that the tread has worn unevenly, affecting the balance and alignment of your tyres.

- Age of the Tyre: Tyres naturally degrade over time, even if they have not been used extensively. Most manufacturers recommend replacing tyres every six years, regardless of tread depth, to ensure optimal safety.

Conclusion

For the best performance, always ensure that your tyres are within the recommended tread depth range, replace worn tyres promptly, and choose high-quality tyres from trusted brands. At CEAT Specialty, we offer premium tyres designed to deliver superior performance and safety, no matter the conditions. Stay safe and ensure your tyres are in peak condition for every journey.

Read the full blog

ceat-speciality:blogs-tags/all,ceat-speciality:blogs-tags/tyre-advice

Get the Grip You Need: CEAT Specialty's Guide to Tyres for SlopesGet the Grip You Need: CEAT Specialty's Guide to Tyres for Slopes

Navigating slopes and uneven terrains is a common challenge in various industries, from agriculture to construction. The right tyres can make all the difference in ensuring stability, traction, and safety. CEAT Specialty offers a range of tyres designed to provide the grip and durability needed for these demanding conditions. In this guide, we will explore the features and benefits of CEAT Specialty tyres that make them ideal for slopes.

1. Enhanced Traction and Grip

One of the primary concerns when operating on slopes is maintaining traction. CEAT Specialty tyres are designed with advanced tread patterns that provide superior grip on various surfaces, whether wet or dry. The FARMAX R2 tractor tyres, for example, feature a stepped lug design that offers excellent grip in wet and moist soil conditions. This design ensures that the tyre can penetrate the soil effectively while also facilitating the ejection of mud and debris as the tyre rotates, preventing clogging and maintaining optimal traction.

2. Self-Cleaning Capabilities

Operating on slopes often means dealing with mud, debris, and other materials that can accumulate on tyres, reducing their effectiveness. CEAT Specialty tyres are engineered with self-cleaning capabilities to address this issue. The FARMAX R2 tyres have an open buttress design that allows for better mud ejection, reducing the build-up of debris on the tyre surface. This feature ensures consistent contact with the ground, maintaining traction and performance even in challenging conditions.

3. Flexible Sidewalls

The flexibility of the sidewalls in CEAT Specialty tyres is another key feature that enhances their performance on slopes. Flexible sidewalls adapt to varying terrains and loads, ensuring that the tyre maintains contact with the ground and reduces the risk of slippage. This adaptability is crucial for maintaining stability and control, especially when navigating uneven surfaces.

4. Durable Construction

CEAT Specialty tyres are built to withstand the rigors of demanding operations. The tyres feature a unique tread compound that enhances their durability and resistance to wear and tear. This compound ensures that the tyres remain stable and efficient, even in challenging environments. The robust construction of CEAT Specialty tyres also means they can handle heavy loads without compromising performance, making them a reliable choice for various applications.

5. Reduced Soil Compaction

In agricultural operations, reducing soil compaction is essential for maintaining soil health and promoting crop growth. CEAT Specialty tyres, such as the FARMAX R2, are designed with a flatter tread that distributes the weight of the machinery more evenly across the soil. This design minimises soil compaction, preserving the soil structure and ensuring healthier crops.

6. Improved Stability and Control

Operating on slopes requires tyres that can provide improved stability and control. CEAT Specialty tyres are designed with features such as bolstered noses at the tread centre and dual step tie bars that prevent mud clogging while adding traction and side hill stability. These features ensure that the tyres maintain optimal performance, even on challenging terrains.

Choosing the Right Tyres for Your Needs

When selecting tyres for slopes and uneven terrains, consider the following factors:

- Terrain Type: Different terrains require different tyre features. For example, hilly areas demand deeper treads for grip, while sandy soils benefit from wider, high-flotation tyres.

- Application: Tyres for ploughing and tilling must be robust, while harvesting might require tyres that prioritise ride comfort.

- Load Capacity: Choose tyres that can handle the weight of your equipment and the typical loads you carry.

Conclusion

By choosing CEAT Specialty tyres, you can ensure optimal performance, reduced downtime, and improved safety in your operations. Invest in the right tyres to elevate your productivity and efficiency on slopes.

Read the full blog

ceat-speciality:blogs-tags/all,ceat-speciality:blogs-tags/tyre-advice

Tyre Disposal 101: Everything You Need to KnowTyre Disposal 101: Everything You Need to Know

Proper tyre disposal is a critical aspect of environmental stewardship and public health. As tyres reach the end of their life, it is essential to understand the best practices and regulations governing their disposal. This comprehensive guide will walk you through everything you need to know about tyre disposal, from collection and recycling to legal regulations and consumer responsibilities.

The Importance of Proper Tyre Disposal

Tyres are durable and composed of various materials, making them challenging to dispose of. Improper disposal can lead to environmental hazards, such as toxic leachates, pest breeding grounds, and fire risks. Therefore, understanding and following the correct disposal methods is crucial for minimising environmental impact and ensuring public safety.

Methods of Tyre Disposal

1. Recycling

Recycling is the preferred and most sustainable method of tyre disposal. Specialised facilities process used tyres into valuable materials for various applications. The recycling process typically involves the following steps:

- Shredding and Grinding: Tyres are shredded into smaller pieces, which can be further refined into crumb rubber. This material is used in products like playground surfaces, rubberized asphalt, and moulded products. (Source: Ecomaniac)

- Tyre-Derived Fuel (TDF): A significant portion of tyre material is used to produce TDF, which can generate the same amount of energy as oil and even 25% more than coal.

- Civil Engineering Projects: Shredded tyres are used in civil engineering projects, such as landslide repair, embankments, and road paving.

2. Retreading

Retreading involves renewing worn-out tyres for reuse. The old tread is removed, and a new tread is bonded to the tyre’s casing using special adhesives and heat. Retreaded tyres are often used in commercial vehicles like trucks, buses, and airplanes, significantly extending their life.

3. Landfilling

Historically, tyres were disposed of in landfills. However, this method is now discouraged due to environmental concerns. Whole tyres are often restricted in landfills due to their bulky nature and propensity to trap methane gas, creating potential risks for fires and pest habitats. Some regions still allow shredded tyres in landfills, but this practice is decreasing.

4. Stockpiling

Stockpiling tyres can lead to significant environmental and public health risks, such as fire hazards and breeding grounds for mosquitoes and vermin. Due to increased regulation and environmental awareness, stockpiling is becoming less common.

5. Export

In some cases, tyres are exported to other countries for reuse or disposal. This practice is controversial, as it often shifts the environmental burden to less developed regions.

Legal and Regulatory Framework

Tyre waste management is governed by a comprehensive set of legal and regulatory frameworks designed to minimise environmental impact, promote recycling, and mitigate health hazards. These laws vary by country and region but share common goals in environmental protection and sustainable waste management.

Disposal and Recycling Laws

European Union: The EU Landfill Directive and the End-of-Life Vehicles Directive make it illegal to landfill whole and shredded tyres and set guidelines for responsible disposal and recycling.

Consumer Role and Responsibility

Consumers play a pivotal role in the tyre production, usage, and disposal cycle. Their choices and actions can significantly impact the effectiveness of tyre recycling efforts and the sustainability of tyre usage.

Choosing Recyclable Tyres

Consumers can start making a difference at the point of purchase by opting for tyres that are easier to recycle. Look for tyres with high natural rubber content and less steel and fibre content, as they are often more straightforward to recycle. Additionally, support manufacturers like CEAT Specialty actively participating in take-back programs or demonstrating a commitment to sustainable practices.

Participating in Recycling Programs

Once tyres have reached the end of their usable life, consumers must dispose of them responsibly by leveraging tyre recycling programs. Many municipalities offer recycling drop-off sites where old tyres can be left for recycling. Some tyre retailers also offer take-back services, collecting old tyres when new ones are purchased.

Best Practices for Tyre Maintenance to Extend Life

Extending the life of tyres reduces the frequency with which they need to be disposed of or recycled. Proper tyre maintenance is good for safety and performance and minimises environmental impact. Here are some maintenance tips:

- Regular Inspections: Frequently inspect tyres for any signs of damage or wear and address issues promptly.

- Proper Inflation: Properly inflated tyres ensure optimal performance and longevity. Under-inflated tyres wear out faster and can even lead to increased fuel consumption.

- Rotation and Balancing: Regular tyre rotation and balancing can even out tyre wear and tear, significantly extending their life.

- Alignment Checks: Ensure that your vehicle’s alignment is checked regularly. Poor alignment can lead to uneven and premature tyre wear.

- Driving Habits: Adopting smooth driving habits can reduce the rate of tyre wear. Sudden starts, stops, and turns can contribute to quicker degradation of tyres.

Conclusion

Proper tyre disposal is essential for both environmental protection and public health. By understanding and following the best practices and regulations governing tyre disposal, consumers and businesses can contribute to a more sustainable environment. Recycling, retreading, and proper maintenance are key strategies for minimizing the environmental impact of tyres. Stay informed about local and national laws to ensure compliance and promote responsible tyre disposal practices. Together, we can make a significant impact on our communities and protect public health while promoting sustainable practices.

Read the full blog

ceat-speciality:blogs-tags/all,ceat-speciality:blogs-tags/tyre-advice

Optimising Truck & Mining Tyre Life: A Maintenance GuideOptimising Truck & Mining Tyre Life: A Maintenance Guide

Truck and mining operations rely heavily on their tyre performance. Downtime due to tyre issues translates directly to lost productivity and increased costs. Maximising tyre life isn't just about buying the right tyre; it's about implementing a comprehensive maintenance strategy.

This guide delves into the crucial aspects of truck and mining tyre maintenance, offering practical advice to extend tyre lifespan and optimise your operations.

Understanding the Challenges

Truck and mining tyres operate under extreme conditions. Heavy loads, abrasive surfaces, varying temperatures, and long hours contribute to wear and tear. Understanding these challenges is the first step towards effective maintenance. Mining environments, in particular, present unique hazards like sharp rocks, uneven terrain, and extreme heat build-up. Truck tyres, while facing different challenges, are still susceptible to damage from potholes, debris, and overloading.

Key Maintenance Practices

A proactive maintenance approach is crucial for maximising tyre life. Here are some key practices to implement:

- Regular Inspections

Frequent and thorough tyre inspections are paramount. Drivers and maintenance personnel should be trained to identify potential problems early. Look for cuts, punctures, bulges, uneven wear patterns, and embedded objects. Early detection can prevent minor issues from escalating into major failures. Develop a checklist for inspections to ensure consistency.

- Inflation Pressure Management

Maintaining correct inflation pressure is arguably the most critical aspect of tyre care. Underinflation leads to excessive heat build-up, irregular wear, and increased risk of blowouts. Overinflation, on the other hand, can cause premature wear in the centre of the tread and reduce traction. Invest in accurate pressure gauges and train personnel on proper inflation procedures. Regularly check and adjust tyre pressure, especially before heavy loads or long journeys. Consider using nitrogen inflation, which can help maintain consistent pressure and reduce air loss.

- Wheel Alignment and Balancing

Proper wheel alignment ensures that all wheels are correctly angled relative to each other and the road surface. Misalignment can cause uneven tyre wear, leading to premature replacement. Regular wheel balancing ensures even weight distribution around the wheel, preventing vibrations and further reducing uneven wear. Schedule regular alignment and balancing checks, especially after impacts or significant mileage.

- Tyre Rotation

Rotating tyres at regular intervals promotes even wear across all tyres, extending their overall lifespan. The specific rotation pattern will depend on the vehicle type and tyre configuration. Consult your vehicle's manual or a tyre specialist for the recommended rotation schedule.

- Load Management

Overloading is a major contributor to premature tyre wear and failure. Adhere to the vehicle's load capacity limits and ensure proper weight distribution. Overloading not only damages tyres but also puts excessive stress on other vehicle components, impacting safety and fuel efficiency.

- Speed Control

Excessive speed generates heat, which is a major enemy of tyre life. Encourage drivers to maintain appropriate speeds, especially in hot weather or on rough terrain. Implement speed monitoring systems if necessary.

- Driver Training

Educating drivers on proper tyre care and driving habits is essential. Train drivers to recognise tyre issues, avoid road hazards, and maintain consistent speeds. Defensive driving techniques can also minimise tyre damage.

- Tyre Tracking and Analysis

Implementing a tyre tracking system can provide valuable insights into tyre performance. Track mileage, pressure readings, repairs, and other relevant data. This information can help identify trends, optimise maintenance schedules, and make informed decisions about tyre selection.

- Retreading

Retreading offers a cost-effective way to extend tyre life. After the original tread is worn, the tyre casing can be inspected and, if in good condition, re-treaded with a new tread. Retreading can significantly reduce tyre costs and minimise environmental impact.

- Proper Storage

When tyres are not in use, store them properly to prevent deterioration. Store tyres in a cool, dry place away from direct sunlight, ozone, and chemicals. Proper storage can help preserve tyre integrity and extend their shelf life.

Choosing the Right Tyre

While maintenance plays a vital role, selecting the right tyre for the application is equally important. Consider factors such as load capacity, speed rating, terrain type, and climate conditions. Consult with a reputable tyre supplier to determine the best tyre for your specific needs. CEAT Specialty offers a range of tyres designed for demanding truck and mining applications, engineered to deliver optimal performance and longevity.

Conclusion

Optimising truck and mining tyre life requires a proactive and comprehensive approach. By implementing the maintenance practices outlined in this guide, you can significantly extend tyre lifespan, reduce operating costs, and improve overall safety.

Partnering with a reliable tyre manufacturer like CEAT Specialty can provide expert advice and access to high-quality tyres designed to meet the challenges of demanding operations. Investing in tyre maintenance is an investment in the efficiency and profitability of your business.

Read the full blog

ceat-speciality:blogs-tags/all,ceat-speciality:blogs-tags/tyre-advice

How to watch out for mismatched tyres?How to watch out for mismatched tyres?

Mismatched tyres can pose significant risks to your tractor's performance, safety, and longevity. Identifying and promptly addressing mismatched tyres is crucial to prevent costly repairs, reduce downtime, and ensure your tractor's well-being.

Common Signs of Mismatched Tyres

- Uneven Wear

Uneven wear patterns on your tractor tyres can be a telltale sign of a mismatch in size or type. If the outer edges of your tyres are wearing more than the centre, it could suggest that the tyres are underinflated. Excessive wear in the centre of the tyres might indicate that they are overinflated. If one side of a tyre wears more than the other, it could be a sign of misalignment or a suspension problem. Cupping, or uneven wear across the tyre's width, is often a symptom of mismatched tyres or suspension issues.

- Vibration

Noticing unusual vibrations while driving your tractor can strongly indicate mismatched tyres. This vibration can manifest in various ways. If you feel the steering wheel shaking or vibrating, it could be a sign of mismatched tyres. Vibrations transmitted to the seat can also be an indicator of tyre-related issues. Mismatched tyres can produce unusual noises, such as rumbling or thumping.

- Handling Issues

Experiencing difficulty steering or maintaining control of your tractor can indicate mismatched tyres. In extreme cases, mismatched tyres can result in a loss of control, potentially leading to accidents.

- Reduced Fuel Efficiency

Mismatched tyres can significantly increase rolling resistance, the force that resists a vehicle's forward motion. When tyres are mismatched, they may not rotate evenly, causing increased friction and energy loss. This can lead to several negative consequences. Increased rolling resistance means your tractor's engine has to work harder to overcome this force, resulting in higher fuel consumption. Mismatched tyres can also impact your tractor's overall performance, decreasing power and acceleration. The added strain on your tractor's components can lead to premature wear and tear, reducing the lifespan of your equipment.

Causes of Mismatched Tyres

- Replacement Without Matching

Replacing a damaged tyre without carefully considering the other tyres on your tractor can have serious consequences. If the replacement tyre is a different size than the other tyres, it can disrupt the balance and handling of your tractor. This can lead to uneven wear, reduced traction, and increased fuel consumption. Using a farm tractor tyre with a different type or construction (e.g., radial vs bias-ply) can also cause problems. Different tyre types have different characteristics, and mixing them can affect your tractor's performance and safety.

- Tyre Rotation Errors

Incorrectly rotating your tractor tyres can lead to uneven wear and mismatched sets, which can have several negative consequences. Mismatched rear tyres can negatively impact your tractor's handling, traction, and fuel efficiency. Uneven wear and reduced traction can increase the risk of accidents and rollovers, particularly when operating on uneven terrain or in challenging conditions.

Consequences of Mismatched Tyres

- Reduced Performance: Mismatched tyres can negatively impact your tractor's handling, traction, and fuel efficiency, decreasing productivity and increasing operating costs.

- Safety Risks: Uneven wear and reduced traction can increase the risk of accidents and rollovers, jeopardising your safety and that of others.

- Increased Wear and Tear: Mismatched tyres can lead to premature wear and tear, reducing lifespan.

How to Check for Mismatched Tyres?

- Visual Inspection: Compare the size, brand, and tread pattern of all your tractor tyres.

- Measure Tyre Dimensions: Use a tape measure to verify that all tyres have the same dimensions.

- Check Tyre Pressure: Ensure all tyres are inflated to the recommended pressure.

If you suspect your tractor has mismatched tyres, taking corrective action is essential. Contact a qualified mechanic to assess the situation and recommend appropriate solutions.

By being vigilant about identifying and addressing mismatched tyres, you can ensure your tractor's safety, performance, and longevity.

Read the full blog

ceat-speciality:blogs-tags/all,ceat-speciality:blogs-tags/tyre-advice

Which tyres deliver the best performance for row crop farming?Which tyres deliver the best performance for row crop farming?

In the demanding world of row crop farming, efficiency and productivity are paramount. Every aspect of your operation, from seed selection to harvest, must be optimized. And when it comes to peak performance, the tyres you choose for your equipment play a crucial role.

At first glance, all tyres might seem the same – black rubber with treads. But that's a misconception! Farm tyre manufacturers invest heavily in research and development to create specialized equipment, not generic circles.

The Right Farm Tyre Makes All the Difference:

Each farm tyre is meticulously designed for a specific purpose. Choosing wisely can:

- Boost Machine Performance: The right tyre can unlock the full potential of your machinery.

- Protect Your Soil: Tyres with proper features minimize soil compaction, safeguarding your precious farmland.

- Increase Efficiency: Optimized tyres can help you work faster while using less fuel.

Picking the Perfect Farm Tyre: It's Not About Price

Finding the ideal farm tyre for your needs can be a challenge. Salespeople might push the most expensive options, but that doesn't always translate to the best fit for your operation. The key is to prioritize functionality. Consider your specific needs and choose a tyre that addresses them, not just your wallet.

Here at CEAT Specialty Tyres, we understand the unique challenges faced by row crop farmers. That's why we offer a wide range of high-performance farm tractor tyres to deliver exceptional traction, durability, and operator comfort in even the harshest field conditions.

Key Considerations for Choosing Row Crop Tyres:

- Traction: Ensuring optimal grip in wet, muddy, or loose soil conditions is vital for efficient operation. Tyres with aggressive tread patterns and deep lugs provide superior traction, minimizing slippage and maximizing power transfer to the ground.

- Load Capacity: Row crop equipment often carries heavy loads. Choosing tyres with robust construction and high load capacities ensures they can handle the weight without compromising performance or safety.

- Flotation: Minimizing soil compaction is crucial for maintaining healthy soil structure and long-term crop yields. Wide flotation tyres distribute weight more evenly, reducing compaction and protecting your precious farmland.

- Durability: Farm tyres endure harsh environments and demanding workloads. CEAT Specialty tyres are built with high-quality materials and robust construction to withstand punctures, abrasions, and everyday wear and tear.

- Comfort: Long hours on the farm shouldn't be a bumpy ride. Our tyres are designed with operator comfort in mind, featuring innovative tread patterns that minimize vibration and ensure a smoother ride.

CEAT Specialty Tyres for Row Crop Excellence:

CEAT offers a variety of row crop tyre options and equipment to suit your specific needs. Here are some of our most popular choices:

- CEAT Farmax R70: This versatile tyre delivers outstanding traction and durability on various terrains. Its lower shoulder angle provides superior grip, while the deep R1-W tread pattern ensures long-lasting performance.

- CEAT Farmax R85: Ideal for tractors and implements operating in challenging conditions, the R85 features a deep lug design and a strong sidewall for exceptional traction and puncture resistance.

- CEAT Torquemax: This VF (Very High Flexion) tyre boasts a higher load capacity at lower inflation pressures, resulting in reduced soil compaction and improved fuel efficiency.

Choosing the Right Tyre:

Selecting the right tyres is just one aspect of a successful row crop operation. At CEAT Specialty Tyres, we'll be your long-term partner in agricultural productivity. Our team of experts can help you assess your specific needs and recommend the perfect tyres for your equipment and field conditions.

Contact your local CEAT Specialty Tyres dealer today to explore our range of high-performance row crop tyres. Let's get you rolling towards a more efficient and productive harvest!

Read the full blog