ceat-speciality:blogs-tags/all,ceat-speciality:blogs-tags/tyre-advice

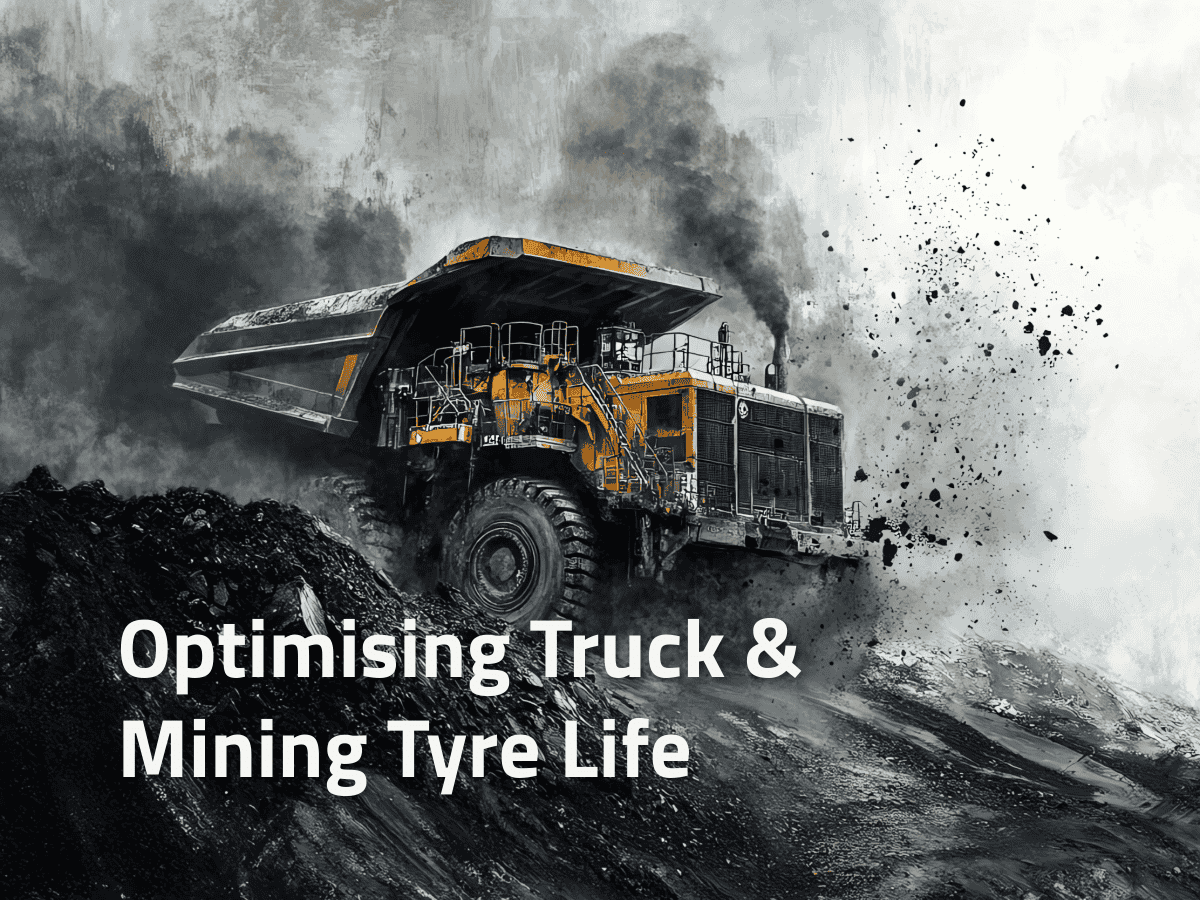

Optimising Truck & Mining Tyre Life: A Maintenance Guide

Sat, 15 Feb 2025 | PRODUCTS

Truck and mining operations rely heavily on their tyre performance. Downtime due to tyre issues translates directly to lost productivity and increased costs. Maximising tyre life isn't just about buying the right tyre; it's about implementing a comprehensive maintenance strategy.

This guide delves into the crucial aspects of truck and mining tyre maintenance, offering practical advice to extend tyre lifespan and optimise your operations.

Understanding the Challenges

Truck and mining tyres operate under extreme conditions. Heavy loads, abrasive surfaces, varying temperatures, and long hours contribute to wear and tear. Understanding these challenges is the first step towards effective maintenance. Mining environments, in particular, present unique hazards like sharp rocks, uneven terrain, and extreme heat build-up. Truck tyres, while facing different challenges, are still susceptible to damage from potholes, debris, and overloading.

Key Maintenance Practices

A proactive maintenance approach is crucial for maximising tyre life. Here are some key practices to implement:

- Regular Inspections

Frequent and thorough tyre inspections are paramount. Drivers and maintenance personnel should be trained to identify potential problems early. Look for cuts, punctures, bulges, uneven wear patterns, and embedded objects. Early detection can prevent minor issues from escalating into major failures. Develop a checklist for inspections to ensure consistency.

- Inflation Pressure Management

Maintaining correct inflation pressure is arguably the most critical aspect of tyre care. Underinflation leads to excessive heat build-up, irregular wear, and increased risk of blowouts. Overinflation, on the other hand, can cause premature wear in the centre of the tread and reduce traction. Invest in accurate pressure gauges and train personnel on proper inflation procedures. Regularly check and adjust tyre pressure, especially before heavy loads or long journeys. Consider using nitrogen inflation, which can help maintain consistent pressure and reduce air loss.

- Wheel Alignment and Balancing

Proper wheel alignment ensures that all wheels are correctly angled relative to each other and the road surface. Misalignment can cause uneven tyre wear, leading to premature replacement. Regular wheel balancing ensures even weight distribution around the wheel, preventing vibrations and further reducing uneven wear. Schedule regular alignment and balancing checks, especially after impacts or significant mileage.

- Tyre Rotation

Rotating tyres at regular intervals promotes even wear across all tyres, extending their overall lifespan. The specific rotation pattern will depend on the vehicle type and tyre configuration. Consult your vehicle's manual or a tyre specialist for the recommended rotation schedule.

- Load Management

Overloading is a major contributor to premature tyre wear and failure. Adhere to the vehicle's load capacity limits and ensure proper weight distribution. Overloading not only damages tyres but also puts excessive stress on other vehicle components, impacting safety and fuel efficiency.

- Speed Control

Excessive speed generates heat, which is a major enemy of tyre life. Encourage drivers to maintain appropriate speeds, especially in hot weather or on rough terrain. Implement speed monitoring systems if necessary.

- Driver Training

Educating drivers on proper tyre care and driving habits is essential. Train drivers to recognise tyre issues, avoid road hazards, and maintain consistent speeds. Defensive driving techniques can also minimise tyre damage.

- Tyre Tracking and Analysis

Implementing a tyre tracking system can provide valuable insights into tyre performance. Track mileage, pressure readings, repairs, and other relevant data. This information can help identify trends, optimise maintenance schedules, and make informed decisions about tyre selection.

- Retreading

Retreading offers a cost-effective way to extend tyre life. After the original tread is worn, the tyre casing can be inspected and, if in good condition, re-treaded with a new tread. Retreading can significantly reduce tyre costs and minimise environmental impact.

- Proper Storage

When tyres are not in use, store them properly to prevent deterioration. Store tyres in a cool, dry place away from direct sunlight, ozone, and chemicals. Proper storage can help preserve tyre integrity and extend their shelf life.

Choosing the Right Tyre

While maintenance plays a vital role, selecting the right tyre for the application is equally important. Consider factors such as load capacity, speed rating, terrain type, and climate conditions. Consult with a reputable tyre supplier to determine the best tyre for your specific needs. CEAT Specialty offers a range of tyres designed for demanding truck and mining applications, engineered to deliver optimal performance and longevity.

Conclusion

Optimising truck and mining tyre life requires a proactive and comprehensive approach. By implementing the maintenance practices outlined in this guide, you can significantly extend tyre lifespan, reduce operating costs, and improve overall safety.

Partnering with a reliable tyre manufacturer like CEAT Specialty can provide expert advice and access to high-quality tyres designed to meet the challenges of demanding operations. Investing in tyre maintenance is an investment in the efficiency and profitability of your business.