ceat-speciality:blogs-tags/all,ceat-speciality:blogs-tags/tyre-care

Tractor tyre maintenance tips

Wed, 4 Dec 2024 | PRODUCTS

Search Further

ceat-speciality:blogs-tags/all,ceat-speciality:blogs-tags/tyre-care

Wed, 4 Dec 2024 | PRODUCTS

While we often focus on the tractor, its tyres are equally crucial in ensuring efficient and productive operations. Just as you wouldn't neglect regular maintenance for your tractor, it's essential to prioritise proper tyre care. Let's explore the significance of tyre inflation and maintenance in maximising your tractor's performance.

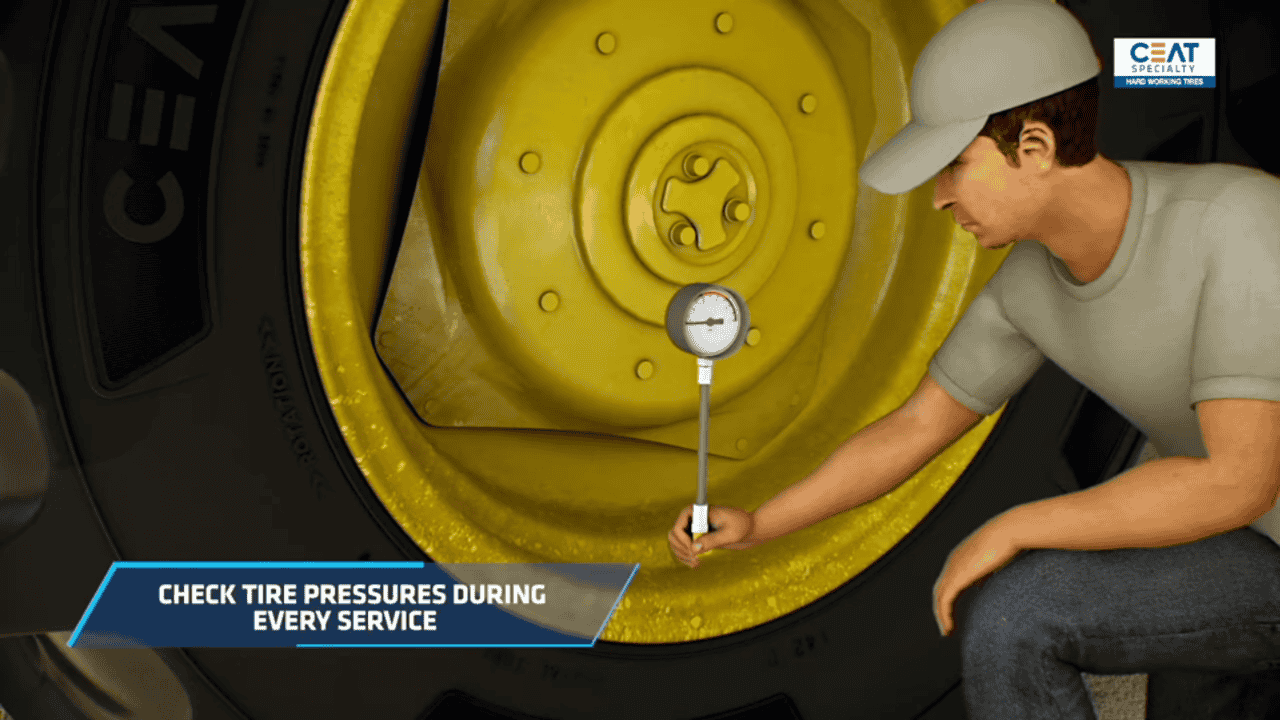

Prioritise tyre pressure checks during every service

Regularly checking your tractor's tyre pressure is fundamental to routine maintenance. Make sure to include a thorough tyre inspection during each service appointment. By consistently checking your tractor's tyre pressure during every service, you can help maintain optimal performance, reduce fuel consumption, and prevent premature wear and tear.

Potential consequences of low tractor tyre pressure

Underinflated tyres can significantly impact your tractor's performance and fuel efficiency. Here's a breakdown of the potential consequences:

1. Power Loss: When underinflated tyres experience increased rolling resistance. This means your tractor's engine has to work harder to overcome this resistance, leading to a loss of power and reduced performance.

2. Increased Fuel Consumption: Underinflated tyres can also increase rolling resistance, leading to higher fuel consumption. Your tractor's engine will need more fuel to maintain the same speed, increasing operating costs.

3. Tyre Damage: Underinflated tyres are more susceptible to damage, such as punctures, blowouts, and uneven wear. This can lead to premature tyre failure, increased downtime, and costly repairs.

The impact of overinflated tractor tyres

Overinflated tyres can also negatively affect your tractor's performance and comfort. Here's a breakdown of the potential issues:

1. Poor Ride Comfort: Overinflated tyres can lead to a harsher ride, increasing operator fatigue and discomfort. The stiffer tyres may not absorb shocks and vibrations as effectively, making the ride less pleasant.

2. Shaking and Vibrations: Overinflated tyres can cause your tractor to shake and vibrate, especially at higher speeds. This can be unsettling for the operator and may even damage other tractor components.

The importance of maintaining minimum tyre pressure

Lowering your tractor's tyre pressure below 16 PSI (1.1 bar) while working on the field is strongly discouraged. However, if you absolutely need lower pressure for a specific field job, do remember to raise it back to the normal required pressure after the job is done.

Here is good advice: Check the tractor tyres with your eyes every time you use the machine visually.

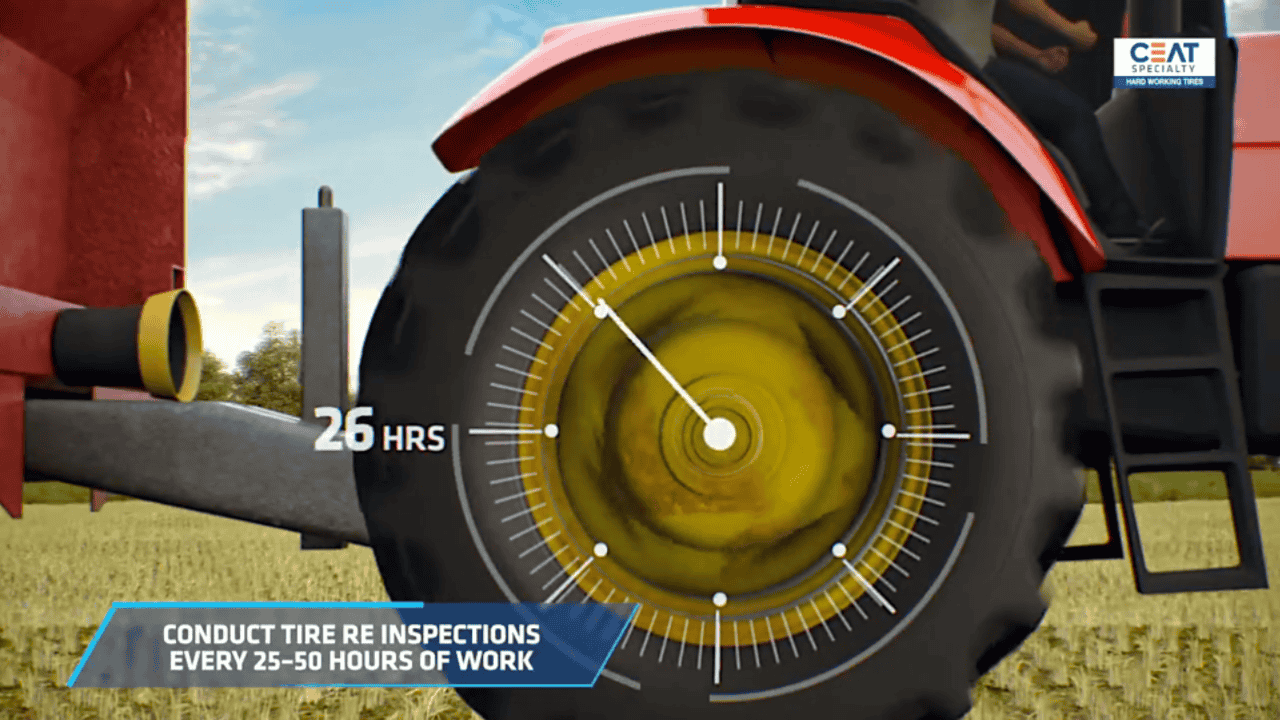

The importance of regular tyre re-inspections

Conducting thorough tyre inspections every 25-50 hours is crucial for maintaining optimal tractor performance and safety. But if the vehicle is new or the tyre has been changed, inspect more frequently. It is possible, for example, that a leak has already damaged the sidewall of the tyre or the tube before you have even noticed it visually.

What else should you check?

All cracks and cuts, any damage caused by nails or thorns or signs of premature wear, such as dry rod or cracking. These are usually easy to tackle with small repair activities, correct pressure, or a change in driving style. Also, check the shape or geometry of the front axle in your four-wheel drive tractor if it looks wrong. It might be causing tyre wear. In that case, get your tractor serviced at once.

The dangers of cracked or corroded rims

Cracked or corroded rims pose a significant safety risk to your tractor and its operator. These issues can compromise the wheel's structural integrity, leading to unpredictable handling and potential loss of control. Always use the rim size recommended by the manufacturer.

Identifying abnormal tyre behaviour

Another trustworthy indicator is on your seat. You should ask yourself what the ride quality or the traction is. You are the best subjective test driver of your vehicle.

Maintain correct inflation pressure

One key to improving ride quality and performance is maintaining correct inflation pressure based on your activity, the load you’re carrying, and the surface you’re driving upon.

Importance of Weight Distribution & Use Behaviour in Tractor Tyre Care

If you know the total weight and load on the rig and the tyres, follow the instructions of the tractor manufacturer. By paying attention to that and other issues, such as weight distribution, you’ll lengthen the service life of your tyres and the vehicle.

By following these key checkpoints and prioritising proper tyre maintenance, you can significantly extend the lifespan of your tractor tyres, improve performance, and reduce maintenance costs.